Captive Screws

are designed to lock into a hole while allowing the fastened components to be detached without the complete removal of the screw itself.

Our team of experts is ready to support you.

A Captive Screw can be locked in place on a parent component without being fastened to a child component

- Captive Screws are typically locked in place via thread locking, press fitting or broaching

- Captive Screws help control costs by minimizing damage to machinery from loose screws and by reducing the need for replacement fasteners

- Captive Screws allows for easier and more ecient repairs due to quick access to components

- Captive Screws prevents damage from loose screws falling into moving parts or electrical circuits as well as the loss of screws

- Captive Screws also provide a longer durability as they do not cause damage to the application after usage cycles; they are permanent, yet allow access into the application

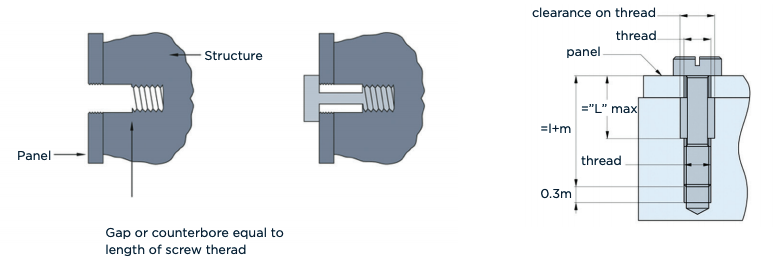

In general, the Captive Screws has a thinner diameter shoulder over the length of the screw with a threaded portion at the end.

An extensive range of Captive Screws are available, ranging in sizes:

- M2-M12 Cold Form

- M8-M80 Hot Form

KEBA Captive Screws are produced, but not limited, to:

- Stainless steel

- Zinc plated steel

KEBA CAPTIVE SCREWS are used in various business units for a wide array of industries such as:

- Automotive

- Electronics

- Machinery And Industrial

- Military And Precision Engineering

- 950 Echo Lan, Suite 220

Houston, Texas 77024 - +1 832-871-5481

- us@kebafastenings.com

USA

- Königstrasse 10C

Stuttgart, Germany 70173 - +49 711 2225 4129

- de@kebafastenings.com

GERMANY

- Kozyatagi Mah. Degirmen Sok.

AR Plaza No: 13/3,

Istanbul Turkey 34742 - +90 216 418 55 79

- tr@kebafastenings.com