BallStud

The KEBA BALLSTUD has been developed to withstand extremely high loads and can be set fully-automatically in a progressive tool or transfer tool. Thus, the downstream operation for the orbital riveting of the ball stud is eliminated providing high-cost savings in return.

The KEBA BALLSTUD can also be set in very narrow sheets as it only requires minimum space. It is very similar to a standard ball stud, but is a lot cheaper in terms of assembly.

Our team of experts is ready to support you.

- High-cost savings

- Fully-automatic processing

- Geometry similar to standard ball studs

- Minimum space requirements

- Suitable for large sheet thickness ranges

- Customized geometries available

- Preservation of the sheet stability due to small pilot holes

Improvements on the current state-of-the-art technology with BALLSTUD can be inserted during the manufacturing of the body sheet metal. The downstream operation is thus completely eliminated oering potentially high-cost savings

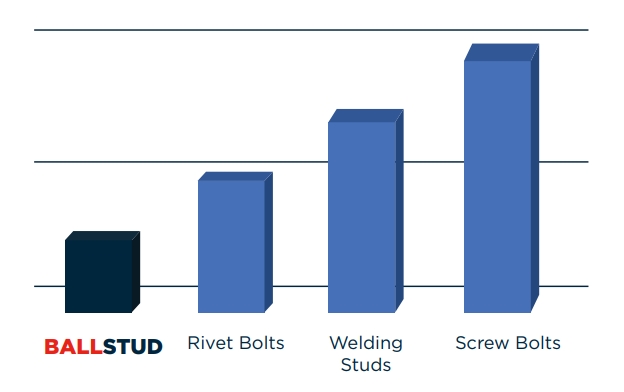

Cost Comparison

- Reduced logistics costs due to the elimination of in-plant transportation between production stages

- Reduced staff and related costs due to the elimination of a downstream operation

- Low space requirements (no downstream system is required)

- Shorter processing times and lower capital commitment

- Lessened warehousing and related costs

- 950 Echo Lan, Suite 220

Houston, Texas 77024 - +1 832-871-5481

- us@kebafastenings.com

USA

- Königstrasse 10C

Stuttgart, Germany 70173 - +49 711 2225 4129

- de@kebafastenings.com

GERMANY

- Kozyatagi Mah. Degirmen Sok.

AR Plaza No: 13/3,

Istanbul Turkey 34742 - +90 216 418 55 79

- tr@kebafastenings.com